1970 Plymouth Cuda Hemi 540 cui Transaxle G-machine project car

Technical specifications of Plymouth Barracuda 1970

| Price: | - |

|---|---|

| Item location: | Budaors, Hungary |

| Make: | Plymouth |

| Model: | Barracuda |

| Type: | Coupe |

| Year: | 1970 |

| Mileage: | 0 |

| VIN: | BP23G0B316530 |

| Color: | Metal clean |

| Engine size: | Hemi 540cui V8 EFI |

| Number of cylinders: | 8 |

| Transmission: | T56 MM6 Transaxle |

| Drive type: | RWD |

| Interior color: | Black |

| Vehicle Title: | Clear |

| You are interested? | Contact the seller! |

Description

RPM-Styling 1970 Plymouth Cuda HemiEuropean built and CAD 3D designed, 540 cui Alu Hemi adapted to T56 MM6 Transaxle, G-machine project

A Hemi Cuda project from 1970 is for sale. The car is a leisure-time car designed for the owners of the RPM-Styling European car-restoration company known for their high quality standards and presently it is offered for sale due to lack of time.

About RPM-StylingThe RPM-Styling is representing the artistic level in the car restoration. The trade considers the quality of the work of our German-Hungarian company among the best three. We have won several Concours d’Elegance prizes in Germany and our cars are successful at every famous trade show of the world, from Pebble Beach to the Villa d’Este.

We began to build this 1970 Hemi Cuda for our own joy in 2009. The objective was to obtain a high-speed two-seater g-machine, with perfect running stability, with suspension that can be set for both street and racing use which has an excellent weight-HP ratio. The Hemi Cuda is our big favourite from our childhood therefore it was normal we are building on this base. Although we spent two years on designing the car and building the tubing-framed body, the BMW 507 and Mercedes-Benz 300 SL types, the main profile of our company, supply us with so much work that we have not had time for our Cuda project for 5 years. In this way our heart breaks but we are looking for an owner who wants a Cuda with a perfect appearance and is finishing it in an easy project since we have already built the hardest part.

The details of the whole project can be seen on our website, together with our other cars RPM-Styling.com

DesignWe did not want to alter the legendary shape of the Cuda of 1970 but we wanted to transfer it into the 21st century. Thus we had to reduce the ride height and the centre of gravity to the level of the current days’ super sports car. We increased the wheels and placed them into the position that complements the car’s shape most. The muscle cars of the 60s and 70s were characterised by a strong back, flat nose and high construction. The back area of the Cuda is a perfect masterpiece, but the nose area is too flat. This is disturbing aesthetically and with the low ride height it can’t receive the huge Hemi engine either. We did not want to put a hood scoop or an accessory with a rectangular shape onto the car, therefore we decided to raise the original ’Cuda hood’ and complement the fender with a nice arch, like a tiered engine case, which gives a powerful European taste to car. With this the appearance became perfect for us, a monster full of power and harmonising with the rear area. We opted for the final colour of the car to be white, with black wheels and black moldings. Only white and black. We did not want to follow the trend of the years 2000 with the shaved and too-bright design. The original handles and bumpers of the Cuda remained untouched, only the rear lock got under the licence plate. We have constructed a luxury-sleeper that is not kitschy, it is mannish, possessing the ancient power, but radiates high quality. In the interior we planned Porsche leather in Espresso, Cognac or Beige colour fits with white excellent.

We designed the car for high speeds, mostly for street use so that it is suitable for long trips and is relatively economical, but with minimal reassembling to be able to make maximum 10 laps on the race course where the lateral acceleration can be over 1G. This is not a small task since we have to consider contradicting designing criteria for the street and race-course use, such as tyre wear, operational heat-degree, fuel consumption and comfort. That is why we had to design the undercarriage to be multifunctional, to over assure the cooling and maximise the body rigidity.

DesigningTechnically we considered everything from high speed perspective. The designing took place with the 3D CAD software where we created the geometry of the undercarriage, together with the frame. The frame of the car is a structure with a very low centre of gravity, the weight distribution is 50-50% on the front and rear axle which can be shifted forward or backward by +-10% respectively onto any corner. For the base setting of the camber we designed replaceable spacer set, with a medium value of -1° for the street and -3° for the race course. The spacers are simultaneously setting the camber and the vertical position of the upper control arms since other control arm angle is required for the street and other for the race course (tyre wear, less oversteer, comfort etc). The camber, caster and toe-in of all 4 wheels respectively the ride height can be adjusted freely. The height of the connection point of the upper control arms can also be calibrated and as such the weight transfer and the roll centre can be fine-tuned. The steering connection point of the front knockle and hubs can also be adjusted. We modelled the basic street and race course settings for the car and during the virtually 3D test we set the rolling axles of the suspensions, the rollin axis of the car, the maximal tire patches bay the weight transfer and the dislocation of each suspension element. We designed and fabricated adjustable coil over shock absorbers made especially for the undercarriage. Te shocks were made from the Swedish Öhlins elements.

Into the external empty shell of the Cuda we built an extremely rigid, low-centre-of-gravity tubing-frame system that runs along the entire car from bumper to bumper, made of 0.150 in. wall thickness cold drawn seamless tube with rectangular tubing base. The tubing-frame provides the spine of the car that supports the drive train and the undercarriage. We designed the rockers with a double-chamber system. We remade the Cuda’s original external rocker with the „C” cross section, made of 0.08-in. thick steel, we closed it with a vertical wall, this became one of the chambers, and we welded a rectangular tubing to it with a 0.118-inch wall thickness, this became the other chamber. We connected the strong rockers obtained as such into the tubing-frame. Under the dashboard there is a strong double frame transferring the twisting power from the spine onto the rockers. This frame holds and simultaneously protects the front area of the cabin, and when colliding it leads out all the power toward the rockers which protect the cabin as strong beams. The front fenders and the hood are held by a complementary and adjustable frame which behaves like a creasing zone when colliding, regardless the tubing frame. The wind-tunnel corridor of the tubing-frame is being connected by an “X” unit that can be dismounted under the torque tube. We designed a removable lower frame under the transaxle. In this way the entire drivetrain can be assembled easily, the tubing frame is closed and rigid, and the „X” frame does not let air from the wind-tunnel under the car. The European law does not permit the construction of the roll cage that can be seen in the cabin, therefore we could build a pipe near the columns, running along the carpets. However the rocker with the closed wall and the tubing frame are suitable to immediately weld in any kind of roll cage.

This is how the body became most rigid, it avoids any twisting, in this way it assures the most accurate fine-tuning of the undercarriage. We built the undercarriage from Corvette C6 Z06 control arms, knockles and hubs, in order to ease the maintenance and replacement. In this way it can be substituted freely for any adjustable and rod end type C6 Z06 control arm. The characteristic of the rear suspension can be adjusted from the neutral to the oversteer range.

Aerodynamics was also an important criterion during the designing. We designed carefully the route of the air coming onto the front of the car. We don’t the air led to the radiator then farther to build up turbulence and braking air-pressure in the engine room. As accordingly we designed for the firewall a tunnel running along the middle of the car and a huge inlet funnel. Minimal air gets under the car. The air entering the radiator is passing the engine then by cooling the exhaust manifold and the exhaust system it goes through the mid-canal of the car, then exiting in the rear through the diffuser it forms the clamping force. The rear diffuser is going to be the bottom of the fuel tank itself. The floor plate of the car is flat beneath, for the clamping force.

The braking force is assured by Brembo super-light discs and calipers. We plan to lead the brake cooling from the collecting elements near the front lights onto the discs, while the rear discs receive a part of the air gained from the wind-tunnel of the car. Through the Tilton race-pedals the braking force distribution can be adjusted during the ride from the transmission lever, between the front and rear axles.

The steering takes place through the steering column of the C6 Z06 with adjustable height and depth. The steering column is connected to the C4 rack&pinion through special joints and for its speed we redesigned the C6 steering knockles, we are supplying the modification design.

For the weight distribution of 50-50% the engine moved behind the front axle, and the transmission before the rear axle. The firewall came backward by 8 inch, the seats got before the rear axle, in this way the driver’s position is right near the centre of gravity. The rear seats disappeared because of need of space for the transaxle, a leathered storage surface can be placed instead, and that can be anything from the entertaining electronics to the luggage rack. The battery tray is behind this, top of the rear axle, on the midline of the car.

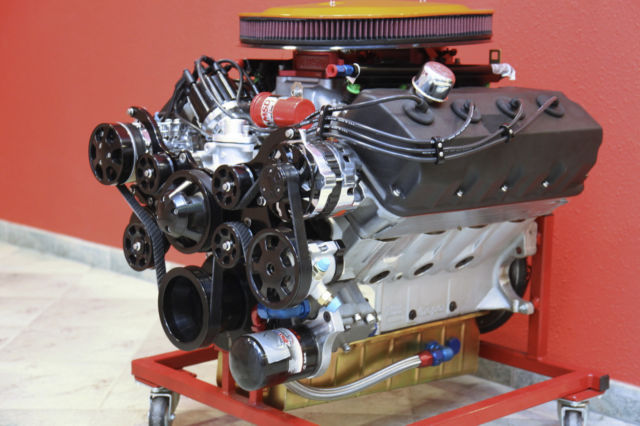

As for the engine we definitely wanted to build in a classic RB Hemi, with the modernisation that fits the body. We wanted an aspiring engine which has to have a big bore and high rpm range because of the high end-speed of the car, but with immediately pedal-reaction at the low RPM range – this is why we all love the old V8 engines. We were thinking of a new cast, stronger designed, strengthened aluminium block, with stage V CNC ported Hemi cylinder heads. The plan was a Hemi with a 540cui World Product aluminium block which was manufactured for us by the FHO workshop. We designed the engine operating with the gear ratios of the T56 MM6 6speed manual gearbox and Getrag transaxle with 3.42:1 rear end ratio and the 26.8 in rear wheel overall diameter to work well up to the possible 200 mph. The engine tests showed up 698HP and 672lb-ft on Dyno. The C6 Z06 torque tube is being connected to the Hemi engine through a specially manufactured billet flywheel and the custom made bellhousing built by the Quicksilver.

We designed a Fast XFI tuned port injection system with the 2*1300cfm throttle body, with all the required sensors, with a distributor modified and adjusted for the EFI and high volume fuel pump. An active traction control operating with the hub-sensors of the C6 Z06 knockles and hubs can be built onto the inlet of the Fast XFI TC.

The engine is being cooled by the a 4600cfm giant Flex-a-lite radiator and fans. The cabin is supplied with a Hurricane manual air-condition system, with special outlet.

We built special long tube exhaust headers for the Hemi built into our tubing frame, which are going under the torque tube with 3-inch diameter end, into the wind tunnel. The entire floor plate is made as a double floorpan with gap, and there is ceramic mesh heat proofing between the two parts, so that the exhaust system that can be glowing at high RPM range using does not heat up the legroom and the cabin which is usually a serious problem with the front engine sports cars. That is why the exhaust system is in the middle under the removable „X” frame so that its produced heat is being led out of the car.

Features & SpecificationsBody – restored by RPM-Styling bodyshop.

1970 Pymouth Barracuda VIN# BP23G0B316530

Year One rear quarter panels, front fenders – new

Tube frame CAD 3D designed in Solidworks

Engine – all new parts, Dyno tested and fine tuned

1 WP088515 Aluminum 4.50" Bore WP Block

1 Block01 Deck/Align Hone/CK 10/Deburr

1 StageV Heads2 Alum. Head Upgrade (best hemi heads)

1 MiscBlockSS Stainless Block Hardware

8 FHO-1.90 Race Exh Stainless w Bead lock

8 FHO-2.30 2.30" Custom Race Intake Valve

1 CC925-16 1.510/128-357 Nascar Spring

1 CC4700-16 1.550" Spring Seat Cup

1 CC741-16 1.550 Steel Retainers

1 FHO-Locks 5/16" Locking Lash Cap System

16 FHO-Viton5/16 5/16" Viton Positive Seals

1 MIL31160 Hemi Competition Oil Pan

1 MIL-21176 Dual Oil System w/Race Pickup Kit includes HV aluminum oil pump

1 Ohio-44404250 4.250" Stroke Race Crankshaft Optional Callies billet in 4.5" strokes.

1 P5249562 Short crank bolt

1 MiscBlockSS Stainless Oil Pan Hardware

1 P3571071 HD Intermediate Shaft Steel

8 CB743HND Race BBC Rod Bearings

1 MS2233HG Race Hemi Main Bearings

1 CC-24-000-5 Custom Flat Tappet Camshaft (hydraulic)

1 CC822-16 440 68 & Up Hyd. Lifters

16 Manton-304 .083" Wall Custom Pushrods

8 CP-CustomPistons Forged Lightweight CP Hemi Pistons

1 TOT-CR9190-255 4.505" 1/16" Race Rings

1 FHO-7100H 7.100" H Beam (opt Oliver billet)

2 Cometic-C5447-051 Hemi .051" x 4.500" Multi-LayerGasket

1 CrankBalance Balance Crank and Assembly

8 Champion 415 RN9Y Spark Plug

1 Amsoil-15 Chrysler Oil filter

1 Head03A Full Radius Valve Job

1 Head04 Cut Spring Seats/Pockets (incl. in CNC)

2 Head06 Resurface Head (incl. in CNC)

1 Head10 CNC Port Cylinder Heads job ($2500 value)

8 CP-15CP1S Pro-Street Hemi Piston Pins

1 FHO-TC-3Bolt Billet 9 Postition Timing Gear Set

1 P4349816 Timing Cover

1 Engine01 Trial Fit/Assemble Hemi

3 Engine Bags Plastic Engine Covers

1 Engine04 Dyno Test Engine (test and tune EFI)

1 PER30874 The Right Stuff

1 PioneerPK-126-25 Crank Woodruff Key

1 FHOStands01 Billet Rocker Stands

1 FHOShafts H.D. Rocker Shaft Set

8 FHO-Rocker1 OEM style hemi intake rocker/ratio’d

8 FHO-Rocker2 OEM style hemi exhaust rocker/ratio’d

1 FHO-Rocker-Springs Rocker shaft springs

1 FHO-VC1 Black FHO Logo Aluminum Covers

1 FHO-Tubes Spun Aluminum Plug Tubes

1 FluidDamp720311 440/Hemi Race Fluid Damper

2 FEL1808 Hemi Oil Pan Gskt.

1 FEL1234 Hemi Intake Gaskets

1 FEL2716 440/Hemi Gasket Set

1 SCE266075-10 Severe Duty Rocker Cover Gkts

1 P3690432 Hemi Electronic Vac. Dist. (modify for EFI)

1 TY44300 426 Hemi Ign. Wire Seals

1 TY75089 Taylor Black 8mm Plug Wires

1 P5007796 Mopar Black HEMI Logo Valve Cvrs

2 P5007499 KB Style Polished Breathers

1 TTI Hemi-218C1 Nickel Chrome Headers – modified to the car

1 CVR1337 Mopar 1.9 HP Protorque Starter

1 FHO2x4BP-UH Underhood Stage V Baseplate

1 FHO2x4Bracket Stage 5 Baseplate Bracket

Dyno tuned, heads retorqued, valves adj. oil and filter changed. Ready to drop in.

Max-durability package.

Block and oil system mods/increased oiling to rockers.

Bronze bushed lifter bores.

There is NO OIL in the engine actually – no oil while the car construction and delivery

Fuel system – all new parts

1 Stage V Intake 2x4 Single Plane Intake 2x4

1 FAST307500 900HP Fuel System Kit Above includes pumps/filters/fittings etc

1 FAST30024B Fast ECU with traction control

2 FAST307603 1300CFM 4150 Throttle Body

1 FAST301101 Main Harness (LT1/LS1)

1 FAST301300 IPU Harness

1 FAST304208 42# Fuel Injectors (8)

1 FAST30700218B 18" Fuel Rails (Blanks)

1 FAST307003 Water Temperature Sensor

1 FAST307004 Air Temperature Sensor

1 FAST307007 1 Bar Map Sensor

1 FAST307015 IAC GM 93-95 Camaro/Vette

1 FAST54020 TPS

1 FHO-EFI-Bungs EFI Weld In Injector Bungs

1 FHO-EFI-Stands Billet Fuel Rail Stands (4)

2 FHO-EFI-Spacers Aluminum Throttle Body Spacers

1 FHO-EFI-Manifold Mach 4 injector bungs/sensors

1 FHO-EFI-File Hemi EFI Programming (incl w EFI system)

1 K&N-E-1980 Hemi Air Filter

1 FHO2x4S-Lid Oval Breather Lid

2 FHO-EFI-Spacers Aluminum Throttle Body Spacers above allows for air filter clearance to EFI throttle bodies and linkage

1 RU632070 #6 Proflex Hose 10’

1 RU632190 #10 ProFlex Hose 20 Ft.

1 RU632200 #12 Fuel Suction Hose

1 RU632140 #8 Flexhose 10 Feet

1 58295R 4600cfm Flex-a-lite Aluminum Radiator and Fan Kit – new parts

72-680 Tilton FLOOR MOUNT PEDAL ASSEMBLY W/ THROTTLE – new parts

Brake sets – new parts

Brembo 1M1.8029A1K 06+ Corvette C6 Z06 Front, Drilled, Black, 6 Piston, 355x32 2-Piece

Brembo 2P1.8013A1K 06+ Corvette C6 Z06 Rear, Drilled, Black, 4 Piston, 345x28 2-Piece

1 set Billet Specialities Premium Tru Trac Serpentine System Hemi A/C serpentine pulley system, black anodized, with power steering pump, with A/C compressor, Polished Powermaster 140 Amp alternator – all new parts

1 Bellhousing costum made by Quicksilver Inc for special adapting Hemi engine to C6 Z06 torque tube – new part

1 6913-07 McLeod RST Street Twin LS7 Clutch Kit – new parts. This part can be undersized for this Hemi

1 Hemi Billet flywheel modified for LS7 Twin Clutch – new part

4 Shock absorbers are built from the swedish Öhlins race elements by us. The characteristics of the shock are designed and built especially into this car. – all new parts

All Corvette C6 Z06 parts were purchased in 2009 from an accidented 2006 car with 10.713 miles in it – so all Corvette C6 Z06 parts are used

C6 Z06 parts in the car – all used parts

4-4 upper and lower control arms

4 Spindles with hubs

4 wheels and tires: Front: 18 inch x 9.5 inch, Rear: 19 inch x 12 inch, Goodyear Eagle F1, Front: P275/35ZR18, Rear: P325/30ZR19 – one of front tires is different.

1 torque tube, with driveshaft, shifter lever, handbrake handle

1 Transaxle with Tremec T56 (MM6) 6 speed manual transmission and 9” ring limited slip (2.5:1 bias ratio) Getrag differential with Z06 trans fluid cooling

2 axle shafts

1 steering column, steering wheel without airbag

Please read the terms and conditions carefully before starting to bid. The car is being auctioned as a project in a semi-finished state, in the condition shown in the pictures. The auction contains only the parts listed here and presented in the pictures. The items not featuring in the pictures are not accompanying the car. The car is not complete, is not functioning, it is being offered for sale in an ´as is´ status. There is no warranty for the car or the parts or the works / designing performed on it, neither opined or real. The buyer is finishing the car at his own responsibility. The finishing requires further designing and work. We made the car for our own hobby purpose, we do not assume liability and guarantee for the works performed so far. The car is currently metal-clean, stainless, it is in our workshop in a raw-steel condition. We undertake to apply a 2-component epoxi prime on the car for the oversees shipping, as required by the buyer. Should you have any other question, we are ready to answer.

PaymentPlease take into consideration that each transaction is binding and final. Winning the auction does not entitle you to come and see the car and decide whether you want to buy it or not, it obliges you to pay. After the end of the auction a down payment of USD 1,000 (one thousand) needs to be paid through PayPal and within 24 hours. The remaining part (outstanding balance) is due within 7 days. We accept PayPal-based and bank transfer to the account of the RPM-Styling INC as the car dealer. The seller is one of the owners of the RPM-Styling INC, as a private individual, so the car is a private car. The expenses related to the bank transfer, the transportation and all the incurring taxes shall be covered by the buyer.

Right to sellWe are auctioning the car beyond the e-bay, too, so we reserve the right to cancel the auction any time.

ShippingThe transportation around the world (worldwide shipping) is dealt by our partner, the American Shipping Services SCS Trading, Inc. You can contact them with the details of the shipping and cost. Website: amships.com, e-mail: [email protected] Florida Tel: 239-297-1836, Los Angeles Tel: 310-750-8195, Hungary Tel: +36-30-370-4836

RPM-Styling Ltd. | http://rpm-styling.com | +36 30 231 7106 | [email protected]

The 'RPM STYLING' logo / emblem / symbol / graphic and name are the registered trade marks and property of RPM-Styling Ltd. The names of listed products and services are the registered trade marks (TM + R + C) of RPM-Styling Ltd.

The products and services of other companies are the registered trade marks of those companies.

© 2003-2017 RPM-Styling Ltd. All rights reserved.