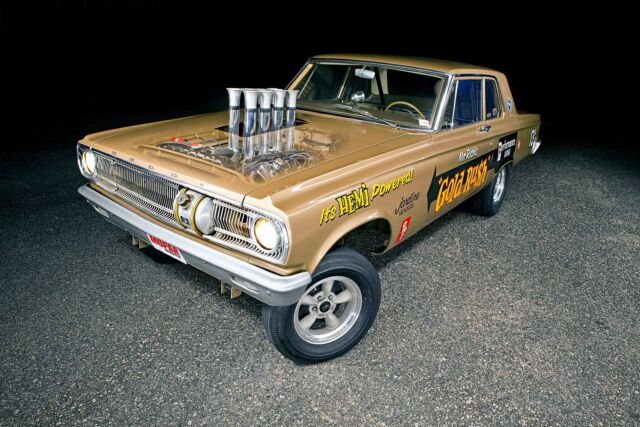

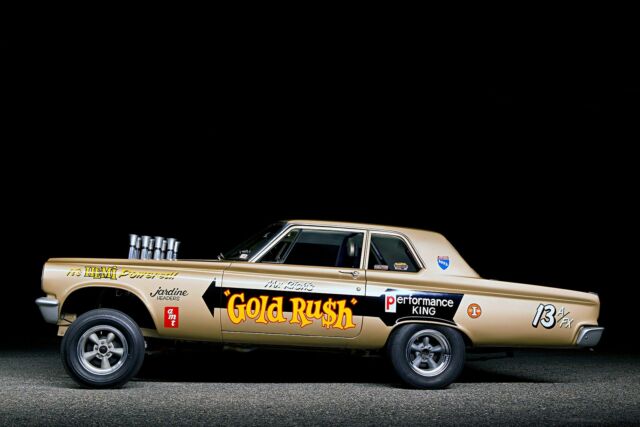

1965 Dodge Coronet A/FX HEMI Gasser Altered Wheelbase Hot Rod Street Legal

Technical specifications of Dodge Coronet 1965

| Price: | - |

|---|---|

| Item location: | Mansfield, Massachusetts, United States |

| Make: | Dodge |

| Model: | Coronet |

| Type: | Sedan |

| Trim: | AFX Altered Wheelbase HEMI |

| Year: | 1965 |

| Mileage: | 50 |

| VIN: | W351161575 |

| Color: | Gold |

| Engine size: | 511 Hemi |

| Number of cylinders: | 8 |

| Fuel: | 93 Pump Gas |

| Transmission: | Automatic |

| Interior color: | Gold |

| Vehicle Title: | Clear |

| You are interested? | Contact the seller! |

Description

This 1965 Dodge Coronet was turned into a two-door, short-wheelbase street dragster by Richard LeFebvre in 2005

as a tribute to the NHRA's altered factory experimental class.

Finished in metallic gold, the car is upholstered in beige with seats from a Dodge A100 van and features added instrumentation

and a roll bar. I acquired it in 2006 after the project was completed.

Power comes from a 511ci Hemi V8 rebuilt with only Dyno tuning and less than 50 street miles featuring a Winberg crankshaft,

Mopar cylinder heads, 10.5:1 pistons, and Hilborn electronic fuel injection. The three-speed automatic transmission is

equipped with a B&M 2,500-rpm stall converter and sends power to a 4.10:1 Sure Grip differential. The build has been featured

inHot Rodand other magazines. I recently changed the coolant, engine oil, and fluids for the transmission, brakes, and rear axle.

This street-legal Coronet drag car is now offered with receipts, build photos, magazines featuring the vehicle,

and a clean Massachusetts title.

Originally built as a four-door Coronet Deluxe, the body was converted into a two-door sedan by Richard LeFebvre in 2005.

Fiberglass front fenders and bumpers were sourced from Fiberglass Plus. The axles were moved forward, and the wheelbase

was reduced to 111 inches, reportedly placing 55% of the vehicle's static weight on the rear tires. The exterior was painted metallic gold,

and the graphics were done by Bob Thompson of Pomona, California. A gas tank has been mounted to the grille. Headlamps,

turn signals, and windshield wipers are retained, and the car is registered for the street.

Aluminum 15″ American Racing Torq Thrust wheels are mounted with Uniroyal tires up front and Mickey Thompson ET Street tires

in back. 11″ x 3″ front drum brakes and 10″ x 2.5″ rears came from a Dodge A100 van and are operated by a modern two-circuit

master cylinder. A walk-around video with the engine idling can be seen below.

The interior is fitted with A100 bucket seats and upholstered with a Dodge A990 kit from Kramer Automotive Specialties.

Vintage-style belts are installed, and the black roll bar was fabricated by Richard LeFebvre. The rear seats were deleted

when the rear axle was moved forward 15 inches.

The shifter is mounted on the steering column, and the gear order has been rearranged to accommodate for the reverse-pattern

valve body on the three-speed automatic transmission. An 8k-rpm tachometer is added on top of the reproduction fiberglass

dashboard, and a Holley EFI display is mounted to the dash face. An added instrument cluster hangs beneath the dash and

includes gauges for water temperature, air/fuel mixture, and oil pressure. 50 miles are shown on the odometer, although true

mileage is unknown and 500 miles reportedly were added by the seller in 13 years. An in-car driving video can be seen below.

The original slant-six engine was first replaced with a 1965 426ci Hemi V8 during the 2005 build. Mike Mancini's

American Muscle Car Restorations in North Kingston, Rhode Island performed restoration work between 2015 and 2018

that included rebuilt transmission, rebuilt Dana 60 rear, new rear springs, new interior, MSD ignition system with crank trigger,

new 40 lb/hr injectors, Holley Engine Management system, additional front frame stiffeners and roll bar reinforcements, rims,

tires, restored dash, brake system upgrade, Dyno tuning, etc.etc.

The engine runs on 93 pump gas and is a stock bore 1965 vintage 426 block stroked to 511 cubic inches using a Winberg billet

crankshaft, Manley billet rods, and forged 10.5:1-compression pistons from Ross Racing Pistons. 3/8″ chromoly pushrods and

a Comp Cams double-roller timing set control the Indy camshaft providing 0.700″ lift with 310 degrees of rotation. Mopar Performance

aluminum hemispherical cylinder heads were machined for 2.25″ x 1.94″ valves and utilize Indy adjustable roller rockers and Chrysler

aluminum shaft stands. A Hilborn aluminum fuel-injection system was converted to EFI with 15-inch aluminum ram tubes and a

Holley electronic control module. Additional modifications include:

- Electric fuel pump, 3/8″ underbody fuel lines

- Milodon oil pump

- 7-quart oil pan with external filter-relocation kit

- Hooker headers, 3″ exhaust, Flowmaster mufflers

- Chrysler electronic distributor

- MSD crankshaft trigger, ignition coil, and Heli-Core wires

- 22″-wide radiator with direct-mount fan

- Mopar Performance high-volume water-pump insert

A dynamometer video can be seen below. The test conducted in March 2018 showed that the car produced 488 horsepower at the rear wheels.

A rebuilt 1965 Chrysler three-speed 727 automatic transmission can be operated manually and utilizes a B&M 2,500-rpm stall converter.

Power is sent to a new Dana 60 rear end with a 4.10:1 Sure Grip differential.

The front suspension includes leaf springs from a 1966 Dodge A100 van, and the beam axle was narrowed 2″ to fit the Coronet frame.

Out back, Mopar Performance 3,800-pound Super Stock leaf springs are paired with extra-length shock absorbers.

The manual steering system works through an aluminum steering box.

The car was featured on the cover of the April 2007 and May 2017 issues ofMopar Muscleas well as in the

December 2016 issues ofHot RodandCar Craftmagazines.

A binder includes photos of the 2004 chassis build, the 2015 engine rebuild, 2015-2018 restoration work, magazine articles, and receipts.

A car cover and four display placards come with the car as well. A drive-by video is presented below, and

footage ofcoldandwarmengine starts also are provided below.

VIDEO LINKS:

https://youtu.be/0Ht2l1gj5ZQ Dyno Tune

https://youtu.be/tcf7yCQ994YWalk around

https://youtu.be/t_08aYWLyzoRide along

https://youtu.be/4aTMHbzoYpgDriving

https://youtu.be/lxP6cnwafVUDriving

https://youtu.be/v0nNXqwk-74Drive By

https://youtu.be/H7Q0R6Fgs28Drive By

https://youtu.be/axK-04qE2H8Drive By

https://youtu.be/ypPRXGSK4SYDrive By

https://youtu.be/-Q0tL2M7C4QCold start

https://youtu.be/tFC5CXCdBVMHot start

PHOTO GALLERY

From Mopar Muscle and Hot Rod Magazine:This Guy Drives His '65 Dodge Funny Car On The Street!Written bySteve MagnanteonDecember 1, 2016John Machaqueiro-Photographer;VIEW ALL 40PHOTOSFacebook

- Google Plus

According to the NHRA's recent year-long promotional program and historical celebration, 2016 markedthe fiftieth anniversary of the Funny Car. According to the house that Wally Parks built, the 1966 Lincoln-Mercury—funded mini-fleet of four flip-top Comet Cyclones marked the birth of the Funny Car. Mark Tyrol begs to differ. With plenty of enthusiasm he says: "The NHRA has forgotten all about the 1965 altered wheelbase Mopars!" Then again, saying 2016 marked the fifty-first anniversary of the Funny Car doesn't quite have the same ring to it.

But history tells us the first public appearance of altered wheelbase, late-model drag strip machinery occurred on January 29, 1965 at Beeline Dragway in Phoenix, Arizona, a full year before Lincoln-Mercury introduced the tube-framed, plastic-bodied Funny Car architecture we still have today. On that breezy desert day, four Plymouths and three Dodges introduced the Beeline crowd to the sight of oddly proportioned, altered-wheelbase door-slammers packing 600-plus horsepower.

These cars were the start of a two-year fever that spawned hundreds of copycat door slammersbased on Mopar and non-Mopar host vehicles. Drag strip announcers and promoters alike quickly defined them as Funny Cars because of their odd proportions, and a legend was born. Getting back to Chrysler's first salvo, a thorough review of the NHRA rule book mentioned nothing against the relocation of wheels beneath the body shell. That detail was of great interest to Ramchargers members and Chrysler performance engineers Tom Hoover and Jim Thornton.

Like all drag racers, they struggled to find traction using the hard, stiff drag slicks of the day. Some experimentation in 1964 revealed the fact that far greater traction was made possible by simply shoving the axle centerlines forward beneath the body of the car. Specifically, in 1964 Chrysler hired The Alexander Brothers (a key Detroit vehicle customization shop) to perform mild, undetectable (to the casual observer) front and rear axle shuffling on two Dodges (Ramchargers and Dave Strickler) and rear axle (only) shuffling on two Plymouths (Al Eckstrand and Tom Grove). Slated for Factory Experimental race action, the surgery wasn't illegal. With added mass supported by the rear tires, static weight distribution broke the 50/50 barrier, despite the hefty iron-headed Race Hemi resting over the front tires. Drag strip elapsed times fell by as much as 4 tenths with no other changes.

For a follow-up in 1965, the tactic was taken to the extreme and it was decided to shove the rear axle forward a full 15 inches, and the front axle centerline another 10 inches. Again, the targeted category was the NHRA's Factory Experimental, a sort of playground where factory engineers could go crazy and have some fun. But just to make sure this more radical fleet of 12 altered-wheelbase 1965 machines was acceptable, in late 1964, Chrysler flew NHRA tech inspector C.J. "Pappy" Hart to Detroit for a pre-Christmas look-see.

He didn't like what he saw. Fearing the latest altered-wheelbase approach was too radical and might alienate paying spectators, Hart barred it from NHRA racing and re-wrote the NHRA rule book to include specific verbiage limiting wheelbase alteration work to no more than two percent of the stock wheelbase total. Since the construction of several cars was well under way at Chrysler (inside a former ambulance conversion garage), the decision was made to keep going forward and to appeal to the AHRA for acceptance in its Ultra Stock class (comparable to NHRA Factory Experimental).

Always second fiddle to the NHRA, the smaller sanctioning body wisely saw the altered wheelbase funny car as a means of attracting competitors, spectators, and advertisers away from the NHRA. And so the 1965 altered-wheelbase Dodges and Plymouths arrived in Phoenix and dominated the weekend with wins in Ultra Stock and Ultra Stock Automatic. Within weeks of their dominating performance, drag racers of every stripe embraced the altered wheelbase strategy and applied it to drag cars ranging from Pontiac GTOs to Rambler Marlins for use on the new match-racing scene.

Sure, the Mercury flip-top formula was superior in most every way, but there's nothing street-friendly about a one-piece fiberglass body shell with no doors. So while cutting-edge professional racers developed the flip-top funny car with each passing year after 1966, steel-shelled, altered-wheelbase door slammers lingered in the sidelines.

By late 1967, the racer's quip "there's nothing older than last year's race car" had claimed many once-proud altered-wheelbase champions. Though a handful have survived the last half century, the vast majority were retired, parted out, and scrapped, which brings us to the core of this feature story: the Gold Rush '65 Dodge.

A lifelong Mopar fanatic, car owner Mark Tyrol is a mechanical engineer whose job involves destructive testing of commercial building materials. It turns out, construction contractors can't just throw structures together using the most convenient materials at hand. From steel roof support girders to aluminum paneling to fiberglass decorative wall molding, every element of modern construction has to pass a variety of safety tests. That way, hurricanes, earthquakes, floods, and other disasters are less threatening to life and property. It's Mark's job to be part of it all.

Mark says, "My job is to blow things up and set things on fire to make sure government certification is warranted." At age 51, Mark is also a Mopar collector. "I have twelve cars, all of them Mopars of one type or another. They include a 1969 Road Runner, 1970 Super Bird, and even a 2011 Challenger. I'm really hooked on the brand. A major factor is how Mopars are over-engineered compared to some other muscle cars. They're stronger, more potent, and have better driveline parts. As an engineer, I notice this stuff.â€

So when Mark decided it was time to add an altered-wheelbase Mopar to his fleet, he reached out to noted Seattle builder Rich "The Performance King" LeFebvre. At first, Mark spotted one of Richard's just-completed cars—a primer-covered '65 Coronet with a tunnel ram 440—in an online auction a few years back. Bidding commenced and Mark won the car. Though he lives in Mansfield, Massachusetts, Mark flew to Richard's Seattle, WA Funny Car factory to pay off the purchase and make cross-country delivery plans. But during the visit, Mark says, "Richard took me for a ride in another altered wheelbase Dodge he'd assembled—the Gold Rush—and when we returned to the shop he said, 'why don't you just buy this one?'â€

LeFebvre's Gold Rush was built in 2005 and was an early member of the Match Bash movement. In a nut shell, many modern hot rodders feel that the original altered-wheelbase era (late 1964 through early 1967) ended too soon. Match Bashers reason, why not build modern-day tributes to them and tame them just enough for regular street and strip use?

And so the Match Bash building style has emerged as a popular alternative today, with growing numbers of altered-wheelbase machines emerging from shops coast to coast. In fact, your author is a proponent of the Match Bach building style and has assembled a few altered wheelbase machines, producing several how-to DVDs and books.

Richard's proposal to Mark made good sense. Compared to the primered, semi-complete Dodge he'd initially sought to bring home, the Gold Rush was virtually completed. With its Hilborn injected Hemi, Mark was saved the task of replacing the primered car's 440 wedge and out-of-date tunnel-ram induction. The attractive gold paint and hand-lettered body graphics were another huge bonus. An amendment to the original deal was made and Mark ended up having the Gold Rush shipped back to Massachusetts in 2006.

Like many buyers of cars other people built, Mark singled out a few areas he wanted to change. The Chrysler 8 3/4 rear axle and 4.56 gears weren't suited to daily cruising, so Mark had Mike Mancini's shop replace it with a stronger Dana 60 and 4.10 cogs. The exhaust system also came in for a second look. Richard LeFebvre was a former punk rock record producer. His low-fi, raw aesthetic encouraged the in-car racket produced by a shorty exhaust system with outlets positioned ahead of the rear axle, but Mike says, "With the rear axle over a foot closer to my ears than in a stock Dodge Coronet, the sound was fatiguing on longer trips." So he had Mike Mancini construct a full-length 3-inch dual exhaust system that reduces sound without harming efficiency. Interior comfort was also enhanced with a full A990 Super Stock interior kit from Kramer Automotive Specialties to add a touch of factory exotica.

Under the hinged steel hood, the big Hemi ran well for a while but eventually suffered a severe failure. At an exhibition drag race event, the oil pump froze. Thankfully, the failure immobilized the intermediate shaft, which halted distributor rotation, and the engine. A post mortem revealed that small bits of metal lodged inside the oil pump had caused the stoppage. Further investigation showed the metal bits were knocked loose from the tops of the valve guide bosses, the result of valve retainer contact at full valve lift. The rebuild was performed by Richard LeVangie of Norwood, MA with extra care taken to assure proper valve-guide clearance.

Though much of the Gold Rush Dodge was left as it was when Mr. Rich LeFebvre built it, a tighter, 2,500rpm torque converter from B&M soaked up some of the sloppy feel. "It had a 4,000 rpm converter that was just too much on the street," says Mark. Also, Mark replaced the stock single-reservoir master cylinder with a modern Mopar Performance plastic-body unit. Mark says, "with two reservoirs, it can lose a wheel cylinder or rubber flex line and still have half of the brake system functional to get it stopped.â€

Mark has made it a point to drive the Gold Rush on the street as much as time allows. Beyond that, he's also very active on the nostalgia drag racing circuit. "I'm no professional, but I appreciate the special attention track owners give me and the other Match Bash racers when we attend their events." With consistent low elevens to his credit, Mark also enjoys car shows, and says, "The first time I brought it to a car show, a moving crowd of people followed me into my parking spot. People can't get enough of the car.â€

So that's the story of Mark Tyrol, the second owner of The Gold Rush altered wheelbase '65 Dodge sedan funny car. Built to celebrate an age that ended too soon, it stands as a monument to the days when Funny Cars still had opening doors. Best of all, Mark makes a point of driving the Gold Rush on the street as much as possible, spreading the gospel with every mile. He even has a Massachusetts vanity plate that reads...AFX1!

The factory authorized altered wheelbase cars retained torsion bars and independent A-arm front suspension. Most independent racers reverted to simpler beam axles and leaf springs, shown here.The fresh Kramer Automotive Specialties A990 Super Stock interior emulates the look of the factory-assembled 1965 altered-wheelbase fleet. The column-shifted Torqueflite surprises most with its crisp detents.Born a four-door, slant-six sedan, original builder LeFebvre used the simple cut-and-splice method to relocate rear axle hump forward 15 inches. All but one of the factory-built altered wheelbase cars was a hardtop.Twin 12-volt batteries are wired in series to assure ample cranking power. Comparing the central fuel fill hump to the contour in the filler panel reveals trunk pan surgery.Note the rectangular aluminum block-off plate below the tail lamp. It is filled in for the optional clear plastic Reverse-gear warning lamp on base-level Coronets.Aside from modern touches like the EFI wiring, fuel rails, and plastic brake master cylinder, Mark's detailed engine bay is period-correct.Original builder Richard LeFebvre sacrificed two Coronet grilles to accommodate this vintage Moon tank. Used by old-school racers running nitromethane, today it serves as a gasoline reservoir.Fast Facts1965 Dodge Coronet

Mark Tyrol; Mansfield, MA

ENGINE

Type: 511ci Hemi

Bore & stroke: 4.280 inch x 4.375 inch

Compression ratio: 10.5:1

Block: factory 1965 Hemi casting

Rotating assembly: Winberg billet crank, Manley billet rods, Ross forged pistons

Cylinder heads: aluminum Mopar Performance Hemi, machined for valve retainer clearance,2.25-/1.94-inch valves

Camshaft: Indy solid roller, .700-/.700-inch lift, 310 degrees advertised duration,COMP double-roller timing set

Valvetrain: Indy adjustable roller rockers, 3/8-inch chrome moly push rods, Chrysleraluminum rocker shaft stands

Induction: Hilborn aluminum FI modified to accept EFI bungs and fuel rails, 15-inchaluminum ram tubes (as per Ramchargers specification with automatic

transmission), Holley electronic control module anddash display

Fuel system: high-volume, in-tank EFI-spec electric fuel pump, 3/8-inch body linesOiling: Milodon high-volume pump, 7-quart oil pan, Milodon ½-inch pick-up tube,

external filter relocation kit, K&N filter

Exhaust: Hooker headers, full-length undercar exhaust system, Flowmaster mufflers

Ignition: Chrysler electronic distributor, MSD coil and crank trigger, MSD Heli-Core wires

Cooling: stock 22-inch wide radiator, MP high-volume water pump insert,direct-mount fan

Output: 600 hp at 6,800 rpm

Built by: Richard LeVangie

DRIVETRAIN

Transmission: 1965 Chrysler 727, cable-operated, full-manual, reverse-pattern valve body

Converter: B&M 2,500-rpm stall speed

Shifter: standard column-shift with rearranged gear quadrants to suitreverse-pattern valve body

Rearend: 4.10 Dana 60 with Sure Grip

Chassis: altered wheelbase, axle spindle center lines moved forward 15 inches inrear and 10 inches in front. Final wheelbase is 111 inches, 5 inches lessthan stock to place 55 percent of static vehicle mass on rear tires at rest.

Front suspension: stock 1966 Dodge A100 van leaf springs and beam axle adapted toDodge Coronet frame. Axle narrowed 2 inches to yield 60 3/4-inch fronttrack width

Rear suspension: floor pan (with leaf spring anchor points) cut free and moved forward15 inches. MP 3,800-pound Super Stock leaf springs (PN 454/455),extra-length MP shock absorbers.

Steering: stock manual steering, aluminum steering box

Brakes: A100 van 11×3 front drums and 10×2.5 rear drums, modern plastictwo-circuit master cylinder

Wheels: American Racing aluminum Torq Thrust 15×5 and 15×8.5 inch

Tires: 7.75-15 Uniroyal (front), M/T ET Street P275/60R15 (rear).

Body: born a slant-six 4-door Coronet Deluxe, converted to 2-door sedanconfiguration by Richerd LeFebvre in 2004. Steel doors, trunk, and hoodwith fiberglass front fenders and bumpers from Fiberglass Plus

Paint: stock 1965 Dodge Gold Metallic by Richerd LeFebvre, graphics by BobThompson/Team Thompson, Pomona, CA. Detailing by Mike Mancini

Interior: 1965 Dodge A990 door panel, carpet, and seat cover kit from Kramer

Automotive Specialties, A100 van bucket seats, reproduction fiberglassdashboard and roll bar by Richard LeFebvre